DETAILS OF GRANITE GRAVEL PRODUCTION LINE WITH 600-700 TONS PER HOUR

DESIGN OUTPUT

600-700TPH

MATERIAL

Coarse, medium and fine crushing of hard rock materials such as basalt, granite, orthoclase, gabbro, diabase, diorite, peridotite, andesite and rhyolite.

APPLICATION

For applications in hydropower, highway, urban construction and other industries, the particle size of the finished product can be combined and classified according to the different needs of users

EQUIPMENTS

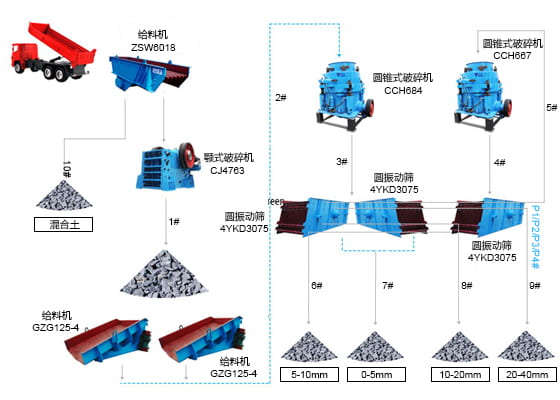

Vibrating feeder, jaw crusher, hydraulic cone crusher, vibrating screen, belt conveyor

BASIC PROCEDURE

The basic process stone is evenly sent to the jaw crusher by the vibrating feeder for coarse breaking, the coarse broken material is sent to the coarse broken cone by the belt conveyor for further crushing, the broken material is transported to the vibrating screen for screening, and the material meeting the requirements of the particle size of the finished product is transported to the finished product heap by the belt conveyor; The material that does not meet the requirements of the particle size of the finished product is broken from the return of the vibrating screen or finely broken conical broken processing, forming a closed circuit cycle. The granularity of finished products can be combined and graded according to the needs of users.

|

serial number

|

name

|

type

|

power(kw)

|

number

|

|

1

|

vibrator feeder

|

ZSW6018

|

37

|

1

|

|

2

|

jaw crusher

|

CJ4763

|

250

|

1

|

|

3

|

hanging feeder

|

GZG125-4

|

2x2X1.5

|

2

|

|

4

|

hydrocone crusher

|

CCH684

|

400

|

1

|

|

5

|

hydraulic cone breaker

|

CCH667

|

280

|

1

|

|

6

|

vibrating screen

|

4YKD3075

|

3x30x2

|

3

|

| serial number | width(mm) | length(m) | angle(°) | power(kw) |

| 1# | 1400 | 20 | 16 | 30 |

| 2# | 1400 | 10+32 | 16 | 37 |

| 3/4# | 1200 | 27 | 16 | 22 |

| 5# | 1000 | 25 | 16 | 15 |

| 6-9# | 800 (four) | 20 | 16 | 11x4 |

| 10# | 800 | 15 | 16 | 7.5 |

| P1-P4# | 800 | 12 | 0 | 5.5 |

Note: This process is for reference only, all the parameters in the figure do not represent the actual parameters, the final result will be different according to different characteristics of stone.

Technical description

1. This process is designed according to the parameters provided by the customer. This flow chart is for reference only.

2. The actual construction should be adjusted according to the terrain.

3. The mud content of the material cannot exceed 10%, and the mud content will have an important impact on the output, equipment and process.

4. SANME can provide technological process plans and technical support according to the actual requirements of customers, and can also design non-standard supporting components according to the actual installation conditions of customers.