Nowadays, the development prospects of the sand industry are getting better and better, leading more and more people to invest in the line, and investing in a sand factory production line is very important. When selecting the crusher, the type, hardness, particle size, output and construction site of the crushed materials should be fully considered.

1. Hardness of material

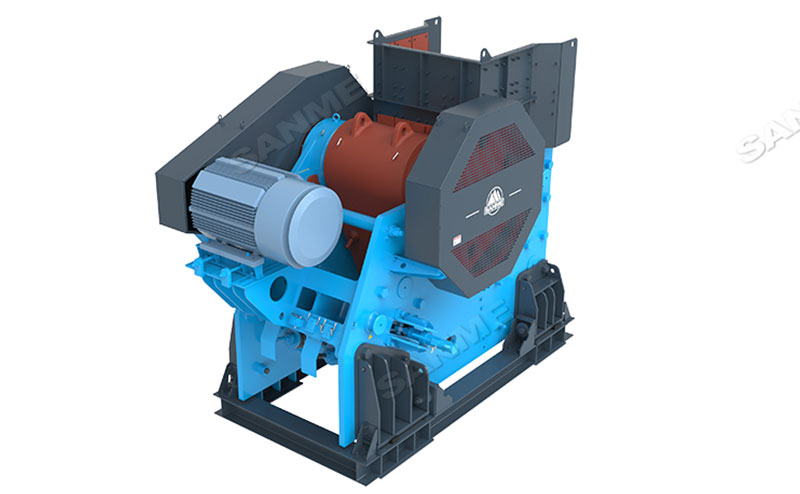

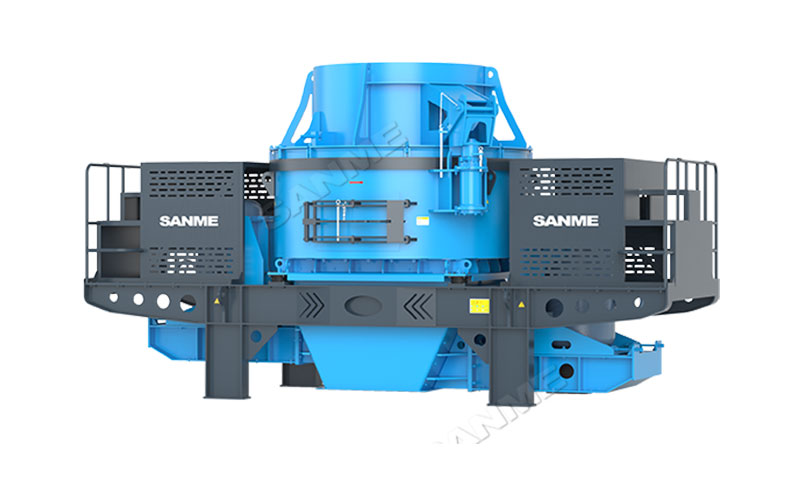

Different kinds of materials have different hardness, under normal circumstances, the greater the hardness, the higher the crushing difficulty coefficient. Crushing hard or medium hard stone, it is appropriate to choose the jaw crushing equipment as a primary crushing equipment, crushing hard or soft stone, you can directly choose cone, counter or hammer crusher. 2. The specifications of the material if the size of the material is larger, the jaw crusher can be used as a primary crushing; When the size of the stone is small and it needs to be composed of a certain level of stone, it is necessary to choose a combined crushing and screening equipment, such as a combined crushing equipment composed of a jaw crusher and a cone or a counterattack type and a hammer crusher.

2. Humidity of the material

The water content of the material will also affect the choice of crusher, when the water content is too large, the fine grained material will be due to the increase in humidity and clumping or sticking on the coarse grained material, thereby increasing the viscosity of the material, reducing the discharge speed, so that the productivity has declined. In serious cases, it will even cause blockage of the discharge port, affecting the normal production.

3. The degree of ore decomposition

The degree of ore decomposition directly affects the productivity of the crusher, because the ore is easy to break along the cleavage plane when it is broken, so the crushing of the ore, the productivity of the crusher is much higher than the crushing of the dense structure of the ore.

4. Particle size of incoming and outgoing materials

The particle size of the incoming and outgoing materials is used to judge the type and crushing level of the crushing equipment required. If the content of coarse particles (greater than the size of the discharge port) in the crushed material is high or the ratio of the largest ore feed block to the width of the feed port is large, the crusher needs to achieve the crushing ratio (the ratio of the particle size of the material before crushing and the particle size of the material after crushing) is large, so the productivity is reduced. If the content of fine particle of the crushed material (close to or less than the size of the ore discharge port) is larger or the ratio of the largest ore feed block to the width of the ore feed port is smaller, the crushing ratio should be achieved, so the productivity is correspondingly improved. If the feed particle size is large and the discharge particle size is small, it is often necessary to two-stage crushing or multi-stage crushing, and if the broken material has a small particle size, it is generally not necessary to multi-level crushing.

5. Output requirements

The output requirement is an important indicator to determine the crushing equipment, the higher the output requirement, the larger the specifications of the crushing equipment required, and the corresponding input and output will increase.

6. Construction site

The specific situation of the construction site is the most direct factor affecting the selection of crusher equipment, such as the size of the construction site, the specific location of the crushing equipment and so on.

You are trustworthy, if you have any questions, welcome to call Shanghai Shanmei shares: 021-5820-5268 Shanghai Shanmei official website (www.shsmzj.com) Email: inf@sanmecorp.com, our technical manager will be online for you to answer.